Checkweighers with chain conveyors and flat belts

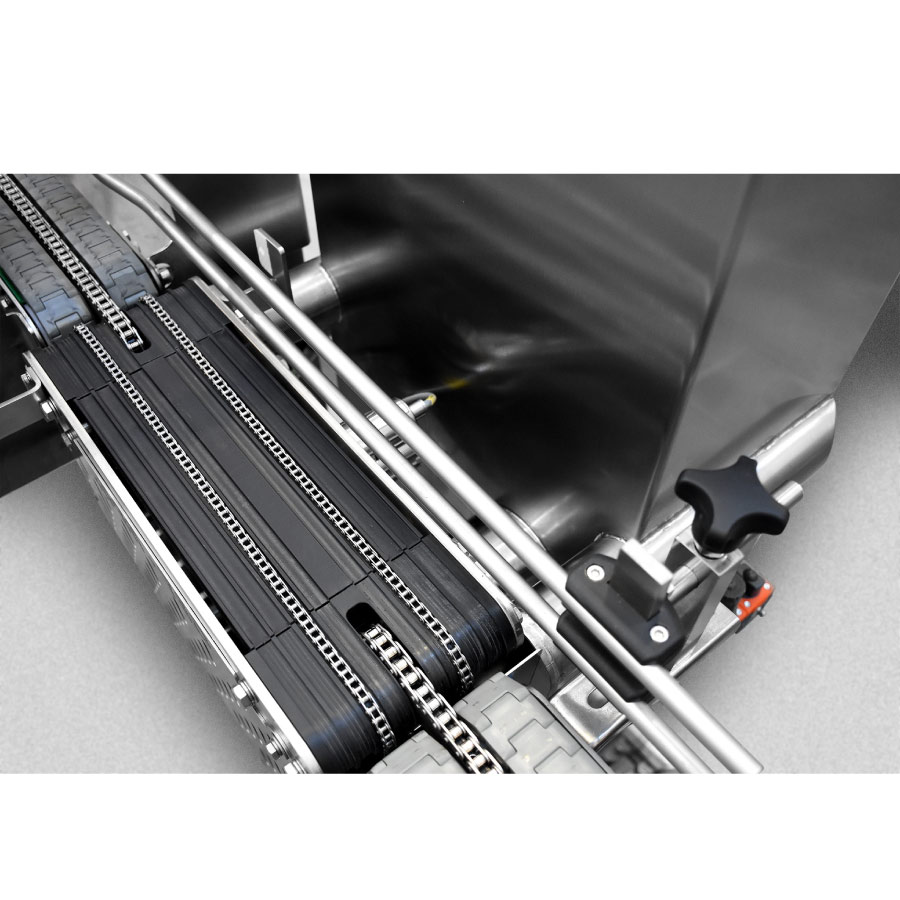

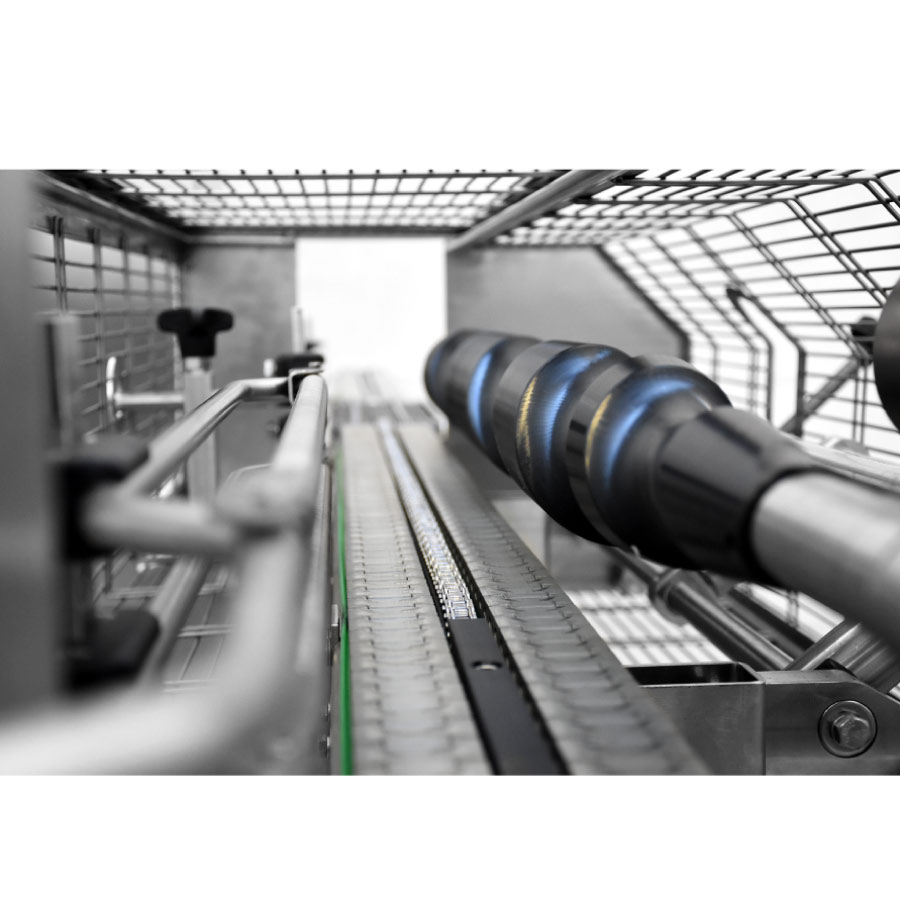

The Antares Vision Group weight control systems for the cosmetics industry are meticulously engineered to ensure precision and reliability in dynamic weighing processes. Utilizing checkweighers equipped with chains and a skid conveyor system, our solutions efficiently manage beauty product containers of varying shapes, dimensions and materials. The transport scheme features adjustable width, accommodating containers such as jars, plastic bottles, and tubes. Optional infeed screw mechanisms provide control over product cadence and spacing, with micrometric adjustments to suit specific requirements. Configurations for high-speed production lines are available to meet diverse operational needs.

Constructed with durable materials such as stainless steel AISI 304 and hard nickel-treated, anodized aluminum, our checkweighers withstand harsh environments and facilitate easy cleaning procedures. The modular design allows for seamless integration into cosmetic production environments, offering flexibility to adapt to evolving product formats.

Antares Vision Group weight control systems adhere to the highest quality standards, meeting MID metrological approval requirements and international quality certifications. Our electronic solutions ensure consistent and reliable performance, providing operators with intuitive touchscreen interfaces for streamlined system management. With the capacity to store up to 254 product recipes, our checkweighers offer versatile functionality and efficient product control.

Furthermore, our systems are designed for seamless integration with Industry 4.0 standards, enabling communication with external systems and facilitating data collection and analysis. Remote assistance management ensures prompt support and minimizes maintenance costs, reflecting our commitment to customer satisfaction and operational excellence in the cosmetics industry.

- Control Panel: colour touchscreen 12”

- Data Processing Electronics: RISC Embedded FPGA

- Self-learning System and Calibration: Included

- Data Collection Software: Included through Ethernet and USB

- Kit for Remote Assistance: Included

- Compliance Industry 4.0: with Bidirectional Communicator

- Conformity: CE, BRC, IFS, HACCP

- Linear Speed: up to 100m/min

- Maximum Speed: up to 600 ppm

- Weight Range: up to 6000 g

- Display Division: starting from 0,5 g

- Protection Degree: IP65/IP68

- Load cell

- Manages very high production speed

- Avoids costly penalties and safeguards brand protection inspecting 100% of the production

- Improves packaging process and increases Overall Equipment Efficiency (OEE)

- Saves costs by reducing product giveaways

- Hygienic design, quick-removal conveyor belts and washable structure speed up maintenance and sanitation

- Easily manages interconnection and remote support, in compliance with Industry 4.0

- HL 3200 CHB

- BR 6000 CHB

- SR 1200 CH

- HR 3200 CH

- HR 600 FTS

- SR 1200 FTS