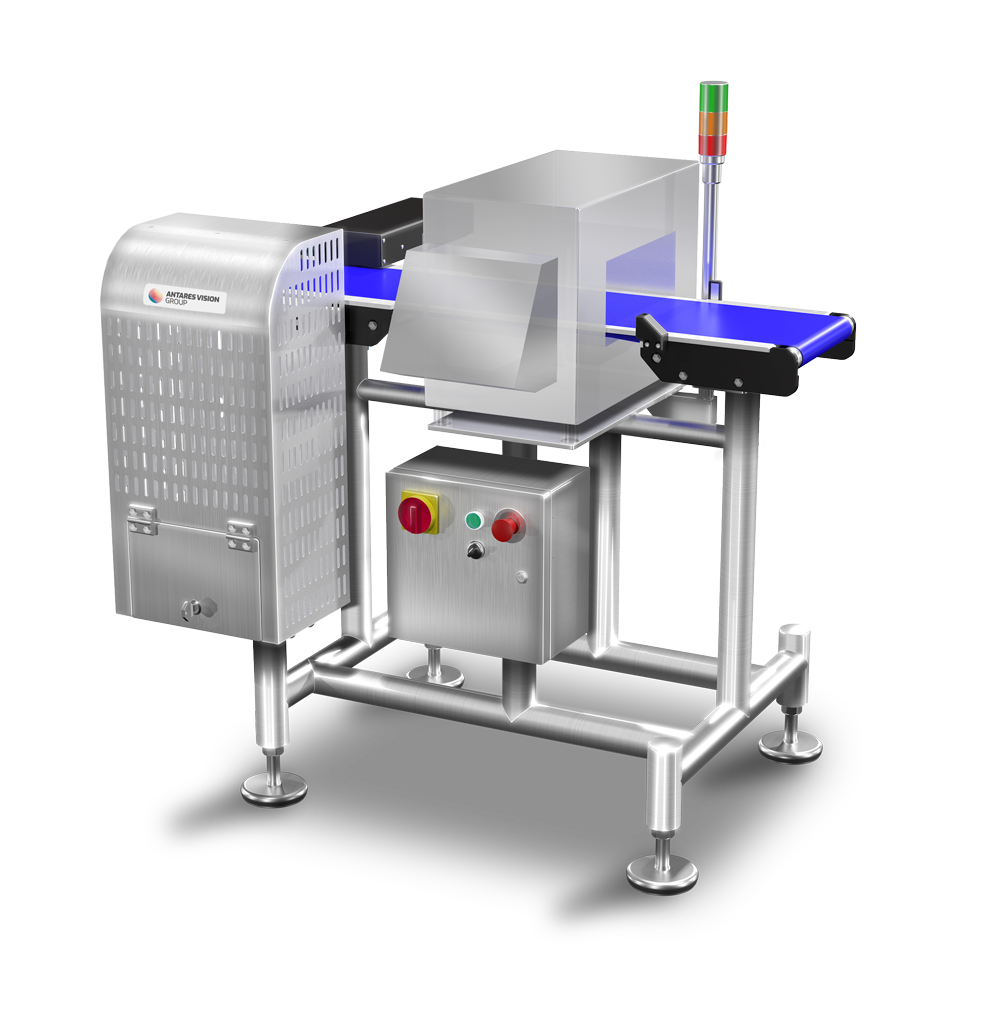

Metal detectors for horizontal products

The Antares Vision Group metal detector unit with a transport system in rubber belt or modular belt is configured to detect metal contaminants in cosmetics products, both unpackaged and packaged in horizontal formats such as foil bags, inner trays, boxes and cases.

Crafted with a support structure made of AISI 304 stainless steel tubes, our solution offers ergonomic design and hygienic integrity, with protection ratings ranging from IP65 to IP69k. This ensures suitability for operation in aggressive cosmetic production environments.

We incorporate metal detector heads from leading global manufacturers, offering a range of models to meet specific performance and budget requirements.

Antares Vision Group metal detectors are designed to work with Dedicated Frequencies, Multifrequency, and Simultaneous Multifrequency modes, optimizing performance for cosmetics products with varying physical characteristics and packaging materials, including light metalized wrappers.

With automatic calibration and an intuitive control panel, our metal detectors are user-friendly for inline personnel. The ability to store 100 product recipes and customize settings for different working conditions ensures precise and stable operation across diverse cosmetics products.

Our configuration offers a wide range of rejection systems, including pneumatic ejectors, air blast ejectors, tilting ejects devices, and pneumatic flaps, tailored to the characteristics of the product and packaging. Plastic or steel bins and contaminated product collection rollers can be combined for efficient handling.

Complemented by accessories such as interchange signals, remote system connection kits, ejection verification devices, and components for pneumatic ejection groups, our metal detector solution provides comprehensive functionality and compatibility with international quality certification standards.

- Metal detector: Dedicated Frequencies / Multifrequency / Simultaneous Multifrequency. Digital, with DSP filters

- Control Panel: alphanumeric display at high visibility reading

- Self-learning System and Calibration: Included

- Login Password: 5 levels

- Conformity: CE, BRC, IFS, HACCP

- Conveyors Length Setup: from 900 to 1700 mm

- Conveyors Width Setup: from 150 to 450 mm

- Speed: variable with inverter in IP65 panel

- Protection Degree: IP65

- Electromagnetic field analysis

- Ensures the absence of metal contaminants, guaranteeing product and consumer safety

- Prevents market complaints and recalls, increasing brand protection

- Guarantees compliance with the most common Certification Bodies guidelines (HACCP, BRC, IFS, etc.)

- Support structure with ergonomic frames, compliant with the principles of hygienic design, allowing quick and effective cleaning operations

- The simultaneous Multi-frequency technology, for compensation and tracking of the product effect, allows to reach very high levels of reliability and efficiency

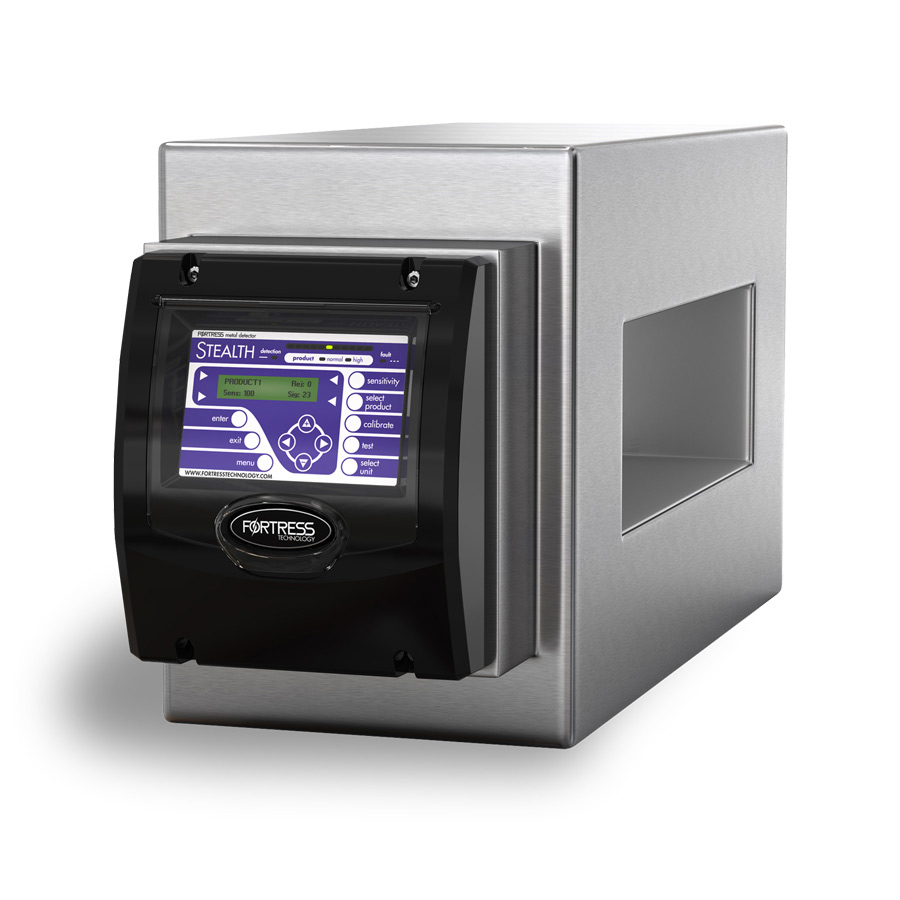

- FORTRESS Stealth

- FORTRESS Interceptor

- FORTRESS Phantom

- MMD multi-frequency

- MOF open-frequency