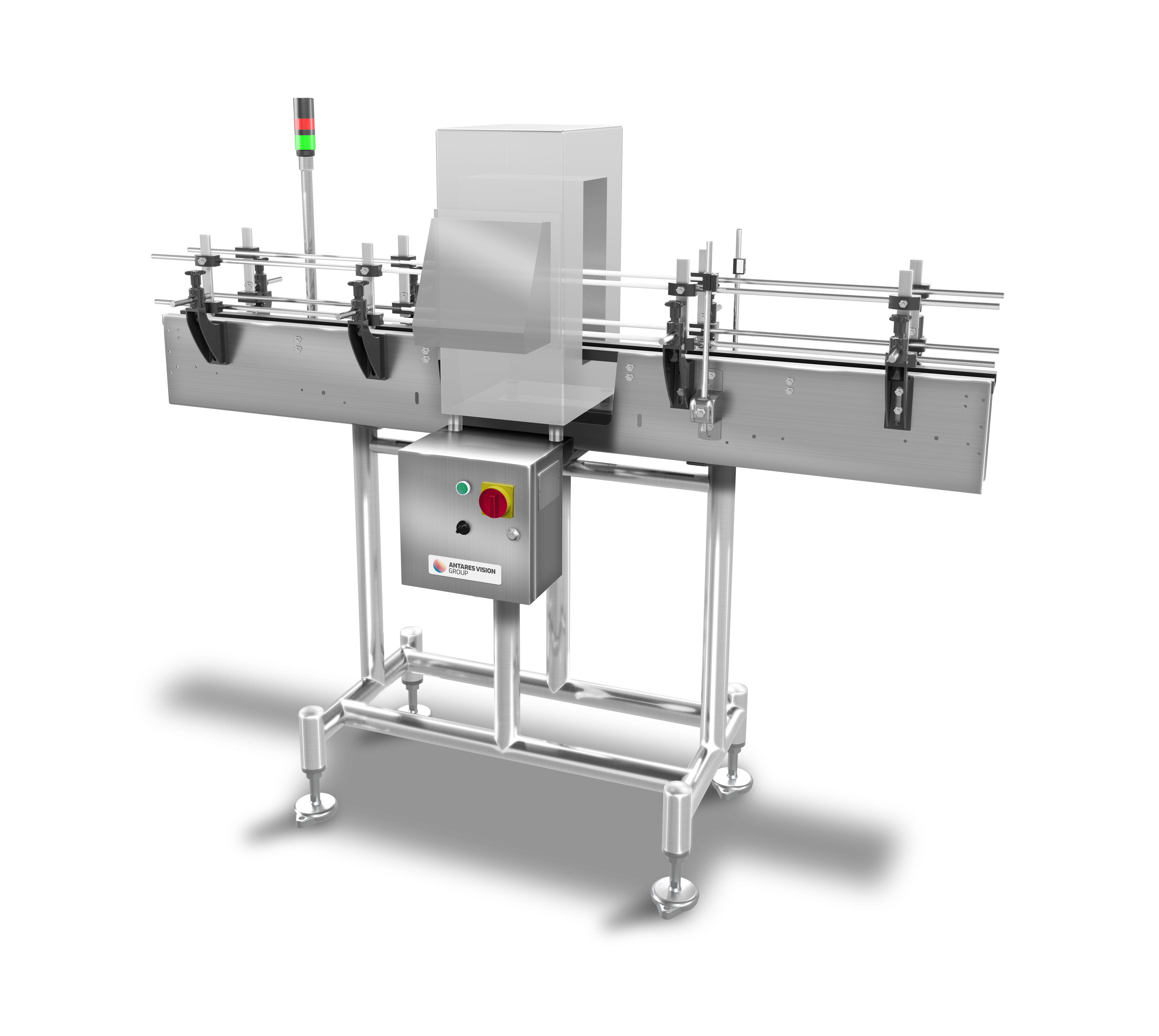

Metal detectors for vertical products

The Antares Vision Group metal detector unit with a modular belt conveyor system is designed for detecting metal contaminants in cosmetics products packaged in various formats, such as tubes, pumps, pens, jars, bottles, and square-based vertical boxes.

Featuring a modular chain transport system, our solution easily integrates into existing production lines, facilitating the lateral movement of cosmetics containers while providing stability through channelling guides.

Crafted with AISI 304 stainless steel tubes, our support structure ensures ergonomic design and hygienic integrity, with protection ratings ranging from IP65 to IP69k. This makes our system suitable for operation in demanding cosmetic production environments.

We utilize metal detector heads from leading global manufacturers, offering a range of models to suit specific performance and budget requirements. Our metal detectors feature advanced signal processing, including DSP processing filters and high immunity to environmental interferences, ensuring exceptional sensitivity and stability for effective metal contamination control in compliance with HACCP rules.

Antares Vision Group metal detectors are designed to work with Dedicated Frequencies, Multifrequency, and Simultaneous Multifrequency modes, optimizing performance for cosmetics products with varying physical characteristics and packaging materials, including light metalized wrappers.

With automatic calibration and an intuitive control panel, our metal detectors are user-friendly for inline personnel. The ability to store 100 product recipes and customize settings for different working conditions ensures precise and stable operation across diverse cosmetics products.

Our ejector systems offer soft-push pneumatic ejection or progressive deviation options, with defective products collected in accumulation tables, idle rollers conveyors, or bins.

Complemented by accessories such as interchange signals, remote system connection kits, ejection verification devices, and pneumatic ejection components, our metal detector solution provides comprehensive functionality and compatibility with international quality certification standards.

- Metal detector: Dedicated Frequencies / Multifrequency / Simultaneous Multifrequency. Digital, with DSP filters

- Control Panel: alphanumeric display at high visibility reading

- Self-learning System and Calibration: Included

- Login Password: 5 levels

- Conformity: CE, BRC, IFS, HACCP

- Conveyors Length Setup: from 1500 to 2000 mm

- Conveyors Width Setup: 150 mm

- Speed: variable with inverter in IP65 panel

- Protection Degree: IP65

- Electromagnetic field analysis

- Ensures adequate handling of unstable products, preventing their fall and consequent line stops

- Ensures the absence of metal contaminants, guaranteeing product and consumer safety

- Prevents market complaints and recalls, increasing brand protection

- Guarantees compliance with the most common Certification Bodies guidelines (HACCP, BRC, IFS, etc.)

- Support structure with ergonomic frames, compliant with the principles of hygienic design, allowing quick and effective cleaning operations

- The simultaneous Multi-frequency technology, for compensation and tracking of the product effect, allows to reach very high levels of reliability and efficiency

- FORTRESS Stealth

- FORTRESS Interceptor

- FORTRESS Phantom

- MMD multi-frequency

- MOF open-frequency