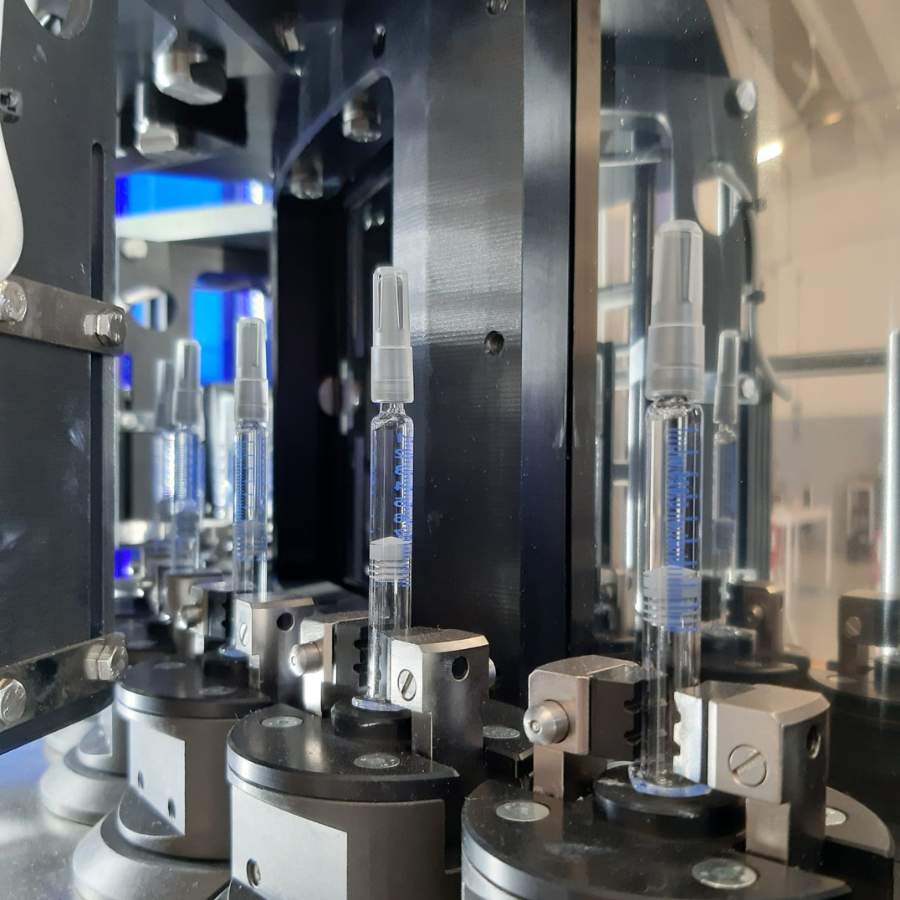

VRI VI for Pre-filled Syringes

The Antares Vision Group VRI for pre-filled syringes targets the highest quality standards through an advanced Automatic Visual Inspection and Container closure integrity testing conducted with integrated high voltage technology with speed up to 400 pcs/min.

Containers processed: SVP glass/plastic Pre-Filled Syringes

Container diameter: Up to 24 mm

Product content: Liquids (water-like, oily, suspension, emulsion, gel)

Processing Speed: up to 400 pcs/min

The Antares Vision Group VRI pre-filled syringes series targets the highest quality standards through an advanced Automatic Visual Inspection and Container closure integrity testing conducted with integrated high voltage technology.

This series benefits from the well-proven Antares Vision Group design allowing for inspecting 100% of the containers’ surface thanks to an additional secondary carousel completing the

container’s dry zone inspection and guaranteeing PFS inspection outright.

This fast, smooth handling system minimizes the risk of product breakages and scratches thanks to individually motorized grippers and guide-less conveying with vacuum-operated starwheels.

HIGHLIGHTS

- Single point product handling improving detection capabilities

- Modular and flexibile design

- High Throughput

This machine detects particles among which: reflecting, nonreflecting,

fibres, floatings and heavy particles. PFS are also inspected to check fill level and cosmetic defects (e.g. flange, needle shield, plunger defects).

- Leak Detection

- Digital Factory modules suite can be optionally embedded to enhance productivity

- Artificial Intelligence integration for Visual Inspection & Predictive Maintenance

- Code verification, OCR-OCV and serialization

- Labeler Integration