ALL-IN-ONE with IE / SER / SIS

ALL-IN-ONE is the new generation of ANTARES VISION GROUP machines which, by integrating multiple and innovative technologies into a single solution, generates a completely new approach to quality control for the food industry.

An innovative solution, unique on the market, capable of combining space optimization and production organization with the need to carry out multiple checks in real time on each individual product. With a single machine installed on each production line, it is now possible to meet the different quality requirements that see the simultaneous use of different technologies.

This configuration implements three different solutions.

A camera placed under the belts and equipped with a lighting system inspects the label and codes on the lower side of the package by exploiting the movement of the two conveyors and the empty space between them.

A second camera with relative illuminator, placed above the conveyor, inspects the label and codes on the upper side of the package.

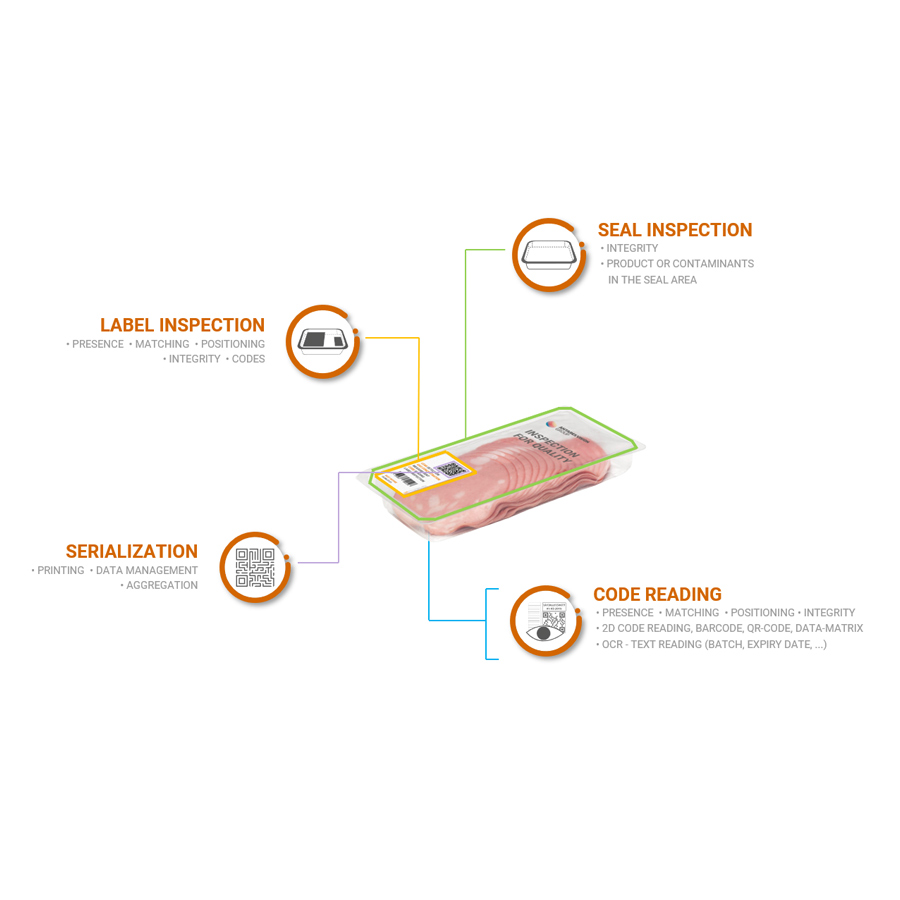

The system is able to recognize and read codes (alphanumeric, QR-code, Datamatrix, etc.), verify the conformity of the label in terms of presence, readability, position, inclination and conformity with the format in production. It also checks the correct correspondence of the lower label with the upper one.

The system can be implemented with the Track & Trace platform, which carries out the serialization of the individual package, both in terms of printing (thanks to an on-board or external printer) and a software dedicated to data management and communication with the management system.

Lastly, a third camera uses hyperspectral technology to identify the presence of organic materials (product residues or foreign bodies) in the sealing area of the tray, even in the presence of opaque and colored packages and films and therefore cannot be inspected with the naked eye or with traditional systems of vision.

A reject system, configurable with air jet or pneumatic cylinder, completes the system.

All this with reduced dimensions, a single user interface that reports the results of each individual inspection, differentiated waste, automatic recipe setting and reduced energy consumption.

- Non-destructive checks in line and on 100% of production

- Inspection of labels and codes, on both sides of the package

- Serialization of the single package

- Control of the sealing area with identification of organic contaminants

- Artificial vision

- Track&Trace platform

- Hyperspectral technology

- Maximum guarantee of bringing to the market a serialized package, showing the correct information and with an intact sealing area

- Reduced footprint

- One control panel

- Quick product changeover

- One electrical/pneumatic connection

- Centralized data acquisition

- One touchpoint and purchasing optimization

- No product passage or synchronism issues

- One maintenance program

- Reduced Total Cost of Ownership (TCO) compared to three single machines

- Compliance with all requirements relating to the information to be reported on the product for: regulatory needs (i.e. EU Regulation No 1169/2011, FDA Food Labeling Guide, etc.), retailers’ requests (i.e. barcodes), and marketing activities (campaigns, promotional codes, etc.)