ALL-IN-ONE with LDS / XR / CW

ALL-IN-ONE is the new generation of ANTARES VISION GROUP machines which, by integrating multiple and innovative technologies into a single solution, generates a completely new approach to quality control for the food industry.

An innovative solution, unique on the market, capable of combining space optimization and production organization with the need to carry out multiple checks in real time on each individual product. With a single machine installed on each production line, it is now possible to meet the different quality requirements that see the simultaneous use of different technologies.

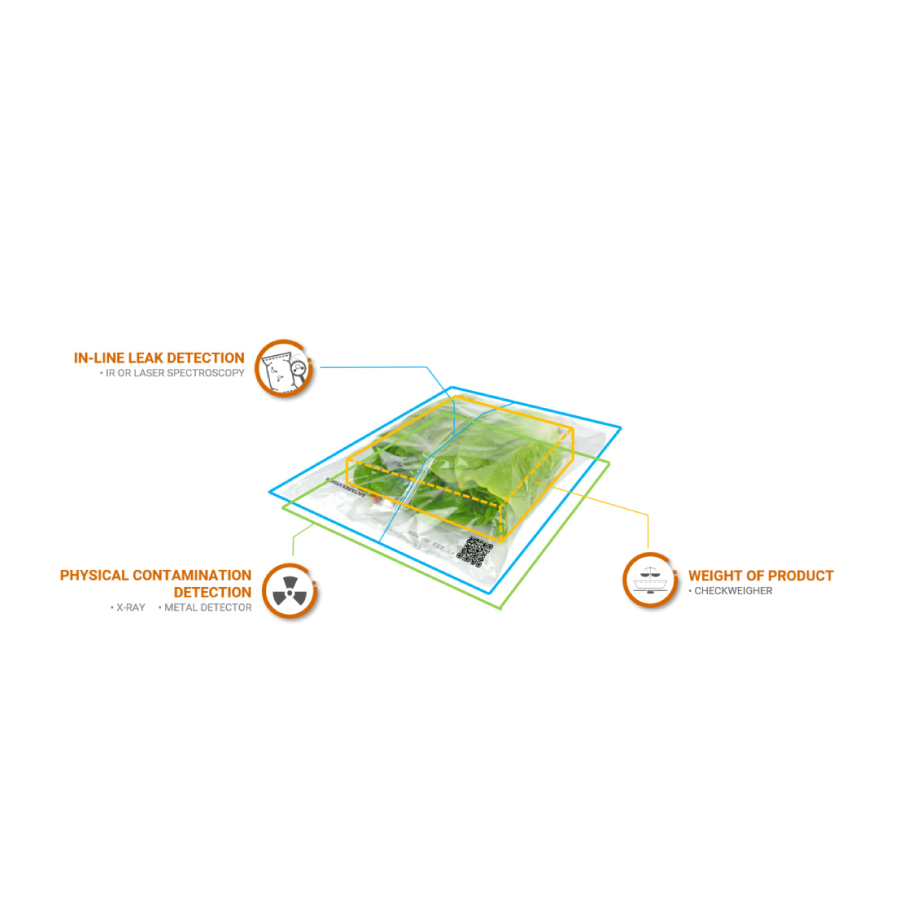

This configuration features three powerful inspection modules.

As soon as the product enters the system, it is inspected by the innovative LDS module for micro-leak detection, which exerts a slight pressure on the package, allowing the gas to escape through any holes and micro-holes. The target molecules in the escaping gas are detected by IR or laser spectroscopy, which is able to detect CO2 (for MAP packaged products), alcohol (for baked products) and specific flavours from the defective package.

In the next step, the product is scanned by a state-of-the-art X-ray inspection system, which is able to identify contaminants of various types, such as glass, stones, metals, bones, high-density plastic, concrete chips, etc., even in the presence of packaging made of metalized polylaminate, tinplate, aluminum and metal clips.

At the same time, the onboard dynamic weighing unit (also available in a version with MID approval) verifies the correspondence of the actual weight with the nominal weight, identifying packages out of weight tolerance with very high precision and repeatability.

All this with reduced dimensions, a single user interface that reports the results of each individual inspection, differentiated waste, automatic recipe setting and reduced energy consumption.

Thanks to this new concept, food producers will no longer have to ask themselves how many inspection machines they need to install on their line. They will simply have to think about which inspections they want to include in their ALL-IN-ONE system.

- Non-destructive checks in line and on 100% of production

- Checking the tightness of the sealing and detection of leaks (holes and micro-holes)

- Detection of contaminants of any nature, in any type of package

- Weight control available with MID approval

- IR or laser spectroscopy

- X-ray inspection

- Load cell

- Maximum assurance of getting product to market intact, free of foreign objects and with the correct weight

- Reduced footprint

- One control panel

- Quick product changeover

- One electrical/pneumatic connection

- Centralized data acquisition

- One touchpoint and purchasing optimization

- No product passage or synchronism issues

- One maintenance program

- Reduced Total Cost of Ownership (TCO) compared to three single machines

- Compliance with all legal requirements (possibility of MID approval) and market (HACCP, BRC, IFS, etc. certifications)